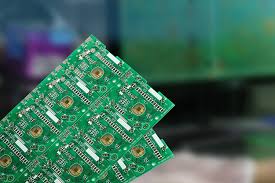

Fast PCB Manufacturing

In today’s world, PCBs are critical for the functionality of electronic devices. They enable a range of applications, including communication between devices and their users. In order to meet the evolving demands of end-users, PCB manufacturers must keep pace with technology and develop new procedures, techniques, and equipment. To do so, they need to stay aware of the emerging trends in fast pcb manufacturing.

One of the most important developments in fast pcb manufacturing technology is the use of 3D printing. This technique layers conductive and insulating materials on a copper-free substrate to create circuit paths and insulation. It is a revolutionary process, and analysts expect it to continue to grow for the foreseeable future. Another development is the use of high-density interconnects, which are designed to fit more components in a smaller space. This trend will allow for more complex electronics and improve battery life in portable devices.

The Internet of Things (IoT) has also made its way into the production of PCBs. This technology involves layers of wireless communications that allow smart home and office devices to connect seamlessly in monitoring and controlling them. IoT has increased the demand for PCBs that can support a range of applications, from telecommunications to medical devices.

Emerging Trends in Fast PCB Manufacturing

As the demand for advanced technologies grows, PCB manufacturers must find ways to reduce costs without compromising quality. They must also find ways to make their products more reliable, which is challenging in an industry that is highly reliant on component suppliers. To achieve this, they are implementing more automated processes and utilizing software to streamline the design and fabrication process. This helps increase the accuracy of manufacturing and ensures consistent quality.

Cybersecurity is also becoming an important trend in PCB manufacturing. It is crucial to implement protective measures to prevent cyber attacks that can lead to system failure and a loss of data. Several methods are being used to prevent these attacks, including implementing authentication and encryption protocols, as well as establishing secure production facilities.

In addition to security, the use of automated optical inspection and functional testing is a growing trend in PCB manufacturing. These methods identify defects, faults, and errors during the production process. This is particularly helpful for space-based systems, where the reliability of components is crucial.

Traditional PCB manufacturing methods often involve time-consuming processes, including designing the layout, prototyping, and production. However, with the advent of advanced technologies and methodologies, the landscape of PCB manufacturing has undergone a significant transformation. Fast PCB manufacturing has emerged as a game-changer, offering accelerated turnaround times, enhanced efficiency, and cost-effectiveness.

Other trends include the development of flexible PCBs and increasing integration of automation and robotics. These trends will have a significant impact on the electronic systems and devices accessible to consumers in 2023. However, for these advancements to be successful, it is essential to work with a trusted and reputable manufacturer that offers fast prototype and low-volume turnkey PCB manufacturing services.